November 2023 newsletter

Contents

Click on the text to jump to the section:

Guild competitions and Committee members for 2023

Programme for 2023 and Tea and coffee rota for 2023

New or refreshing spinner programme

Bursary Information and Equipment Hire

My Crafty Life (correct version)

Yorkshire button making workshop

Choosing the right yarn for a project - video

Spinning and weaving groups in Somerset

18th Century Dyeing in The South West

If you would like to contribute to our next newsletter which will go out in early 2024, please get in touch with lauratyley1@gmail.com.

Chairperson's message

To all those that have been on holiday - welcome back.

As you know, we have been meeting at Fivehead for a few months and, although the hall was lovely, it will be good for us to be going ‘home’ to the refurbished hall at Hatch Beauchamp in October.

We have a full program of speakers for the rest of this year and for next year so a big ‘thank you’ to Hilary Tudgee and Sophie Forague for organising this and we look forward to many interesting talks.

As Christmas is approaching, don’t forget that there is a Christmas social in December. Bring your own lunch and a secret Santa present ( if you are taking part) to the value of up to £5 that is textile related.

I have decided to step down as chairman at the next AGM in February so there will be a vacancy for this post. It has been a pleasure being more closely involved in the workings of the Guild and the members but I feel now would be a good time to hand over the reins.

I look forward to seeing you all again soon,

Marilyn

Guild competitions and committee members

The theme for this year’s competitions is HOLIDAY MEMORIES”.

The dates are:

November 18th Weaving

It would be great to see more entries and they give an excellent opportunity to use some of that stash.

Committee members from March 2023:

Marilyn Biggs: Chairperson

Ian Waite: Honorary Treasurer

Norma Sanders: Honorary Secretary

Mandy Stead, Hilary Tudgee and Sophie Fovargue: Membership Secretary, Fleece Fair organiser and programme organisers

Jan Hopwood: Demonstration organiser

Sue Prosser: Tea/coffee rota and raffle organiser

Georgina Vye: Facebook page administrator

Kathy Wright: Sales page, Newsletter editor

Other roles:

Phil Hocking: Librarian

Jenni Llewellyn: Librarian

Guild programme 2023/24

October 28th: Daniel Harris of the London cloth company will be talking about his work rescuing woollen mills and making cloth. Spinning competition.

November 18th: Janet Phillips will be talking on “Designing Woven Fabric” Weaving competition

December 17th: Christmas social.

January 20th 2024: Brian Bond will be speaking on “My journey in Natural Dyeing”. Sales of seeds, dried dye stuffs and dyed wool fibre/yarn

Tea/coffee Rota – for the rest of 2023

November 18th

10.30 – 12.00: Brenda L & Brenda H

12.00 – 1.45: Pam Mitchell & Liz Lawrence

Reserves: Julie R., Sue Latimer, Tricia R., Willow Iredale

One-hour spinning workshops for beginners or interested people

Please email Kathy Wright (Kathywright24@gmail.com) by the second Saturday of the month if you would like to join. There is no charge. We’ll meet in the small room at Hatch Beauchamp.

Time – 10.30 til 12

November: Plying. Bring along a spinning wheel, two bobbins with spun yarn (don’t have to be equal), empty bobbin, yarn for leader, lazy kate or shoe box wide enough for your bobbins and two knitting needles size 8 /4mm.

January: What you can do with wool tops/batts. Bring along a wheel, tops, carders, 2 lengths of dowelling or 2 big knitting needles or 2 x 12 “ rulers.

February: Drum carding. Bring along a drum carder if you have one and wheel. Clean fleece or tops if you would like a go. Knitting needle, tweezers, carder or dog brush.

March: Introduction to combing. Bring along a spinning wheel, bobbin, leader, dog comb, afro comb, mini wool combs, long staple (3 – 5”) washed fleece.

April: Blending on carders and drum carder and blending board. Bring along a spinning wheel, bobbin, leader, hand carders, coloured fleece/tops.

May: Introduction to Andean plying and Navajo plying. Bring along a Spinning wheel, bobbin of yarn, lazy kate (or shoe box equivalent), empty bobbin.

Bursary Information and Equipment Hire

Did you know that the Somerset Guild offers bursaries to help members pay for courses at the Association Summer School or any other course connected with our craft? Please contact the Guild in the usual way to find out more information.

You will be asked to write stating what the learning will be, how much it costs and what you can bring back into the Guild to benefit other members. Generally there would be an expectation that you show the fruits of your learning in some way – a short talk and exhibition of work, or teaching at a Guild Skills Day.

Equipment to Hire

Did you know that the Guild has equipment for hire? There is a deposit, returnable when the item is received and checked by a committee member. A hire charge of 5% of the deposit per month is made.

Vacancies

Chairman

This vacancy is effective from the AGM in February. The chairman is a role that holds the Guild together and it cannot function without one.

The chairman works closely with a competent and well-organised committee that does most of the heavy lifting and is an important part of the Guild

If you want to know what is involved, get in touch with Marilyn or ask the secretary to forward you a copy of the job description.

Newsletter Editor

After this newsletter, Laura Tyley will take over from Kathy Wright as our newsletter editor. You can contact Laura at 07807055015 or lauratyley1@gmail.com.

My Crafty Life – Patricia Ilsey

(incorrect version included in the last newsletter. Sincere apologies to Pat and Marilyn - The Ed.)

They say that it’s always the quiet ones! And that was so true of our speaker in March, who was our very own Pat Ilsley.

Pat is known for her very fine spinning but her talk gave us an insight into her life before spinning became her passion.

Pat’s first craft recollection was of knitting a fair isle jumper, no mean feat at the age of 10 and Pat kept up with her knitting whilst working in a shop, factory and an office after leaving school at 15.

When she later joined the Forces as a fighter plotter and she took up dressmaking, cake decorating, crochet and embroidery to while away her time off duty.

After leaving the Forces Pat moved to Torquay, getting from A to B on a Lambretta scooter and then a Tiger motorbike which was upgraded to an Ariel Arrow sports model. It was while in Torquay that Pat married her first husband and moved to Yeovil where she carried on knitting, cake making and dressmaking.

Eventually Pat and her husband moved back to the Torquay area where Pat added painting and decorating to her skills by working for a builder. Pat then returned to Yeovil as she got divorced. But, never idle, Pat carried on knitting and started cake making in earnest after getting married a second time. She supplied a shop in Shaftesbury and later knitted for the Natural Dye Company who exhibited her knitting at the Chelsea Craft Show.

Unfortunately Pat lost her husband after a few years.

Some time later a friend suggested she write to a pen pal and she struck up a correspondence with a man in New Zealand, who she later married on a beach there. After moving to New Zealand Pat joined a craft group in the village and it was here that Pat decided that she give spinning a go. She gained the New Zealand Quality Mark which meant that she could put labels on her work, some of which was part of a showcase that was shown around New Zealand. Also her work was included in the National Exhibition which was taken to Australia.

Buying their own home in New Zealand meant that Pat had to learn more skills as the house was a ‘fixer upper’. These included floor levelling and varnishing, and fixing the roof. The garden also needed some work so Pat learned drystone walling and path laying and logging. After converting a large water tank into a shed Pat also took up beer and wine making and even had her own still!

After her husband passed away after short illness Pat returned to the UK bringing her spinning wheel with her. It’s the same one that you see her with at Guild meetings. After joining the Guild she has had several entries in the National Exhibition and taught several people the art of fine spinning during our Skills Day meeting.

Now that you are giddy from Pat’s adventures, here is a list :

Knitting

Cake decorating

Dressmaking

Crochet

Embroidery

Spinning

Painting and decorating

Drystone walling

Producing alcohol

Yorkshire Button Making Workshop - with Pam Martin

At the September Guild Meeting I and fourteen other members chose to attend the Yorkshire Button making workshop led by Pam Martin who teaches a variety of crafts under the title of “Somerset Stitch”.

While many of us may be acquainted with “Dorset Buttons”, Yorkshire Buttons is a lesser known craft which seems to be a more recent innovation possibly dating from the early 20th century.

Dorset Buttons are made over a metal ring, whereas Yorkshire Buttons are made over a round card template approximately 4 cm- 2.5cm in diameter with 12 equal distance notches. A long length of thread is woven across one side of the card in rather the same way you might wrap a flower loom, the thread is then worked around the spokes created by the wrapping process until the card is full. The thread is worked under two spokes and over one, gradually rotating the disc as each stitch is worked. Once no more rounds can be worked the button is eased off the card and is stuffed either with wool or a button former or old button or a bead the final length of thread is threaded through the edge loops and pulled tight and fastened. This stitch can be reversed threading the yarn under one spoke and over two and gradually rotating round the disc and this produces a smoother, more “tight flower petal” appearance than the former stitch which forms a “Whelk Shell” appearance with 12 ridges

Almost any yarn can be used from fine perle cotton to quite bulky wool, variegated yarns are very striking, or two separate coloured yarns can be used in rotation or beads be added for dramatic effect.

While this is clearly a very flexible technique which can add handmade coordinating buttons to homemade garments and accessories. I was particularly struck by how much the technique worked well with wool, whereas Dorset Buttons lend themselves more to fine cotton and linen yarns and therefore are more appropriate for cotton or linen textile items the Yorkshire Buttonworks exceptionally well with woolen yarn.

Pam is a very skilled teacher, she came prepared with handouts and all the equipment and materials we need. She told us how during that dreaded Covid Spring of 2020 she had discovered the technique and had sat in the garden exploring all aspects of the technique and she bought a beautiful display of buttons she had made.

If you are looking for a truly portable craft, consider Yorkshire Button making, all you need is some old buttons of various sizes (to stuff your button with) a blunt embroidery type needle, a small piece of strong flexible card and a few yards of yarn or thread and a pair of scissors, All can fit into a small tin in your pocket or handbag. Apparently you can purchase a plastic button ring, but Pam warned that she did not feel they worked as well as the card gives a little ease which is required when removing the button from the card.

If you want to make coordinating buttons for your beautiful knitted, crocheted or woven creations, consider Yorkshire Button making. They are quick, fun and satisfying to make and will add a real Haute Couture finish to any outfit or accessory and will save money on expensive commercially made buttons.

I am sure I am not alone in saying what an enjoyable, well organized and worthwhile workshop this was and one I would recommend to all those who missed it in September.

Sophie Fovargue

WESTHOPE CRAFT COLLEGE - Braid Society Weekend

Westhope College is in an area of outstanding Natural beauty in Shropshire, a part of Britain I am not familiar with. The weekend was held on the 23-25 June 2023 and the weather was wonderful throughout. Being a keen “Braider” I have been a member of the Braid Society for a couple of years, they are an active group holding an International Biannual Conference, Meetings, Displays face to face and zoom workshops, they also publish a yearly Journal called “Strands” which is issued to all members and is a useful and fascinating report on a variety of Braiding topics.

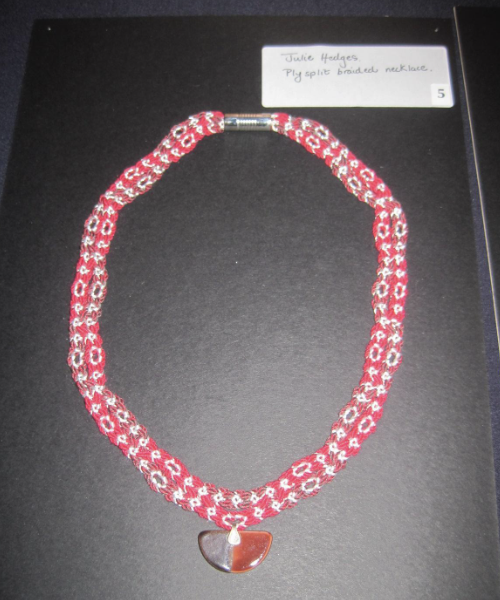

When I was asked to hold a workshop on Ply Split Braiding for the April Skills Day I felt I should try to improve my rather basic skills in this craft, so I leapt at the opportunity to attend the Westhope Weekend which offered a whole day workshop with Julie Hedges on Ply Split Braiding with a Kumihimo workshop on the following day with Debbie Richardson.

I decided to travel by train to the event and was fortunate to have an uneventful experience considering all the strikes and delays that rail travelers have experienced this year! The college is privately owned by an old lady called Anne Dyer who herself is a renowned crafter. The college is set in beautiful grounds with a Wild Flower Meadow which was in full bloom in June and was filled with orchids and other meadow flowers.

Accommodation at the college is very comfortable, many of the rooms are en-suite and the food is all home cooked high quality fare, with some of the fruit and vegetables supplied from the walled vegetable garden. The weekend started with a Barbeque in the garden on Friday evening.

There were 15 members attending the weekend, so although I did not know anyone it was a small friendly group and I soon made friends. Most of the Braid Society members are also members of the Guild of Weavers Spinners and Dyers so we all had much in common. The college has a library sitting room, filled with topical craft books and was a nice place to sit, craft, relax and chat.

The Ply-Split Braiding workshop was with 3 ply cords and was working on a recent designs of Julie Hedges called “Interlinking Circles and Squares”, I must admit this is quite an advanced technique and struggled with it, but did manage to produce a reasonably respectable sample by the end of the day!

In the middle of the day there was a “Sales Table” of equipment, books and materials pertinent to Braiding.

In the evening Julie Hedges gave a formal talk and slide show on “Traditional Ply-Split braiding outside India” - this was a fascinating talk which included some new research as to origins of the technique. She also brought a large display of Ply-Split items she had collected or made over the years.

There was also a display of members' work called “The Travelling Show” which was very inspirational, with a wide variety of braiging techniques on show.

On Sunday there was a choice of two workshops, “Icelandic Foot Weaving “ with Kay Hawkins, this is similar to inkle weaving, but done with a backstrap and held taut with your foot!

I chose to do the Kumihimo Workshop with Debbie Richardson, which was working with 16 Tama (bobbins) on a Marudai making “Hybrid Braids'' experimenting with two braid structures at once, this was a innovative technique she had been taught at the last Braiding Conference which was held in Denmark in 2022. These experimental techniques push the boundaries and open up a host of possibilities for the craft.

If like me you are interested in some of the Braiding Crafts such as Tablet and Inkle Weaving, Ply-Spitting, Kumihimo, Nalbinding and Lucet braiding; or indeed in Sprang, Farosoe Cords and Bands, Sami Weaving, Loop Braiding, Whipcording, Fist-braiding , Passmeterie or Button Making do consider becoming a member of the Braid Society. With these crafts many are rare, to almost extinct and there is a cultural need to rejuvenate these crafts and learn their fascinating archeological and historical legacy.

Sophie Fovargue

Report of Demonstrating

We had a great day demonstrating at the mid Somerset show in August. The weather was sunny and warm and there was a lot of interest in the spinning, the children especially loved taking turns winding the handle on the drum carder and finding out how it works smoothing the fibre that is then lifted off once the drum is full ready for spinning.

Taking part were: Lyn Blower, Debbie Hills, Lyn Perfect and Sue Prosser

YouTube video Choosing the Right Yarn for a Project suggested by F Wilks

Fay says that this lady talks about knitting (mainly) from a mathematical and scientific angle, especially this latest post.

This is so good and if you know of any you tube snippets or podcasts others way find useful/interesting/inspiring please send them for inclusion in the newsletter.

Spinning and Weaving Groups in Somerset

The spinners and weavers workshop, Sweethay Close, Staplehay near Trull. A small group meets on the second and fourth Mondays of the Month (you can do one or both) at 10 am until 2 ish or as long as you like. £5 for hot drinks, goodies, hire of hall (heating included). Lots of equipment can be used during the sessions – carders, combs, drum carder. Contact Kathy Wright 07766092121 for more info.

Spinning group near Hinkley Point, Bridgwater. Four members have recently started this group meeting once a month in each other’s homes at the moment, usually on Wednesdays. They find it really good for exchanging ideas and experiences and a great motivator. Please contact Sue Prosser. Email sueprosser8@gmail.com

An HJS Studio Pattern: Spinning Great Sock Yarn

Sue Prosser found this really interesting article. She obtained permission for its inclusion in the Newsletter.

It's funny how you can stumble across something that works totally by accident. That's what happened for me and learning how to spin yarn for socks that wears well. My very first pair of handspun socks are still in use, and only needed their first repair—reinforcing a slightly worn area—four years after I made them. Although I don't wear these socks daily, they are worn when doing chores on particularly cold days, so they suffer more stress than being worn in street shoes.

I've since spun yarn for about a dozen pairs of handknit socks. Two pairs taught me what my first pair didn't— that 100% wool doesn't make a long-lasting pair of socks, even though they were made of medium-type, strong Shetland wool. Another pair taught me that even really well designed sock yarn can be eaten alive by unlined, unpadded rubber barn boots. Another pair taught me that socks must be carefully stored off season, and don't trade a good pair of socks for the ones that were bug eaten after you gave them to your sister. Another way to put it is to be sure the recipient appreciates what goes into sock yarn, and knows how to store them so they don't become munchies for bugs.

Here's my experience of spinning sock yarn that works well. Although there are no guarantees, there's a lot of trial and error summarized here for you, so you don't have to team from your own mistakes.

Elsewhere on my site is a generic sock pattern that will allow you to knit a sock that fits whatever foot you're knitting for, using whatever type yarn you desire, while another page has information on how to make knee socks that stay up wearing after wearing.

Sock Requirements

Here's what I require of socks I make:

Comfort! I have wide feet, making it difficult to find shoes that fit well, so my socks are made from fingering weight yarn to minimize the fitting problem.

Warmth! Wool is so wonderfully warm, and handspun more so than commercial wool sock yarns.

Durability! I don't want to make a pair of socks that gets holes every other time they're worn. Darning socks is kind of satisfying, but I don't want to have to do it daily like women of yore.

Beauty! Why bother putting the time into making socks if they're not going to be attractive?

Elasticity! Who likes a sock that stretches out the first time it's worn and then bunches up every time after that? Good elasticity makes the sock snap back and fit better each wearing.

Easy care! OK, so I can't machine wash and dry these socks. But they're very easy to handwash, and dry in a matter of hours.

If my handspun, handknit socks don't meet these requirements, they're not worth the time to make. I want something I can cherish for decades, even pass down to my kids (but only if they appreciate them! :)

Fibres

Wool is the best primary fibre for socks. Most wools are quite elastic if not over processed. Wool is very warm and cushy, and it's easy to find and spin.

There are lots of different types of wool. I avoid using Merino and similar fine wools, as they don't stand up to abrasion very well. Some people like to make socks designed to be felted, and fine wools are good for felting, but my one experience of felted Bond x Corriedale slipper-socks suggests fine wools, even felted, get holes in them very quickly, and are about impossible to repair, besides!

The wool used needs some definite crimp. It doesn't need to be a lot, but it needs to look more like crimp than wave. Crimp is a large part of what gives wool its elasticity.

Border Leicester, and some of its crosses, are my first choice for sock wool. My second choice would be Romney. Both breeds vary tremendously in their wool characteristics. What I look for is:

Staple length of around 5-7 inches / 13-18 cm in length (unstretched). I wouldn't use wool less than 3 inches / 7 cm in length (unless, perhaps, it's a down breed) because it would probably be too fine to resist abrasion well. And I would be hesitant about wool longer than 8 inches / 20 cm because it's likely to be harder to prepare and spin and be wavy rather than crimpy so less elastic than I want.

5-10 crimps per inch / 2.5 cm. More usually means a fine wool. Fewer often means a somewhat harsh wool, and less elasticity.

Somewhat soft or silky handle. My feet aren't particularly sensitive to harsh wools, but my legs are. I need a fibre soft enough to be comfortable on my legs.

Some folks recommend down breeds for socks. I haven't used them, but would imagine their combination of strength and bounce would be ideal. I would still be inclined to blend in some mohair, to be on the safe side.

The next most important fibre is mohair. I blend about 10-15% mohair by weight into the wool for sock yarn. You can use kid, yearling, or adult—I like yearling best as it's less expensive than kid, but still very soft and adds a lovely halo.

Why mohair? It effectively takes the place that nylon has in commercial sock yarns. Mohair adds strength and resistance to abrasion, the prime enemy of socks. You don't need a lot; 15% by weight is plenty. Percentage by weight, in my usage, means you weigh a given amount of wool, use a calculator to figure out what 15% of that weight is, then weigh that much mohair. Blend all together very thoroughly.

The only other fibre I've used in socks has been angora. I added about 10% angora by weight to a sock fibre blend that was previously 85% Romney and 15% yearling mohair. I was making knee socks for winter chores, so wanted the extra warmth; plus the angora softened the somewhat harsh feel of that particular Romney wool.

Other fibres can be added. Alpaca and llama add warmth. Silk adds sheen and softness. Just about anything can be added in small amounts, so long as at least about 70% of the fibre is wool, and a minimum of about 15% is mohair.

Of course, make sure the fibre you use is in good condition. Don't choose the fleece with a break in the middle of each lock. Also, if using machine-carded fibre, make sure the fibres weren't broken in processing. Pull fibres out of the roving or batt and look at their length. Are they all about the same length, or are parts much shorter? Hold it up to the light. Is the fibre even carded, or can you see little knots (called neps) of tangled fibre? Either can be a sign of broken fibre and may not make a long-lasting sock yarn.

If you're considering having a custom sock yarn roving made at a mill, first check what types of blends their equipment and staff can handle. Then, to make sure the entire batch is well blended, so you have the right proportion of wool to mohair throughout, have the roving carded twice. I have found this makes the fibre much easier to spin as well as more consistent in texture. It's really worth the extra money—my sock class students always comment on the quality of the sock roving I provide.

Important update in 2008: I no longer recommend using machine-processed roving! I've made a couple pairs of socks from specially-designed sock roving I had made from good wools and mohair. Although beautiful and easy to spin, the socks I've made from these rovings have not held up in wear for very long at all. The performance of the yarn has been strikingly poor compared to yarn from handprocessed fibres. As yet I have no experience spinning sock yarn from commercial top, so can't comment on that.

Fibre Prep and Spinning Techniques

You can spin good sock yarn using various preparation and spinning techniques.

Combing

The fibre can be handcombed (or you can use a commercially combed blend) if the fibres you're blending are all quite close to the same length. This is really important, for as you draw off your top from the combs, the longer fibres will tend to come first. Whether those longer fibres are wool or mohair doesn't matter—your yarn won't have the right mix of fibres for elasticity and abrasion resistance throughout the spun yarn.

An issue with commercially combed fibres in my experience is that they seem to have the crimp, and therefore elasticity, somehow processed out. I don't know how this happens, but definitely most commercially combed top doesn't regain its bounce even after washing. If this is the route you want to go, buy a little and spin, then wash it first. Check to see how much elasticity is in the fibre afterward. Superwash top seems to have a similar problem, in my limited experience of it. Remember to choose something other than fine wool top, if you want to use commercially combed fibres for your socks.

Carding

The fibre can be handcarded, drumcarded, or machine carded (though I no longer recommend machine carded fibres for socks). Although the finished yarn may be a little more prone to pilling and wear-and-tear than when combed fibre is used, those of my socks have been drumcarded have given very good results.

True worsted spinning methods will give a dense yarn that will stand up to wearing quite well. Long draw spinning will loftier and cushier. I like long draw, because it's very fast and easy for me. Ultimately, the choice may be determined by what preparation method you chose, and what pattern, if any, you want in the finished socks. If the sock is to be in a lace pattern, fair isle, or any type of textured stitch that you want to show well, worsted spinning will be a good choice. My socks are usually just stockinette stitch and ribbing. The interest lies in the colours, so I can card layered batts and spin them long draw with successful results.

Either way, make sure the fibre is well prepared. Yes, I'm harping on this point! Fibre with lumps will make yarn with bumps. Bumps may be OK for the leg of your sock, but in the foot they're bad news. Bumps abrade faster, causing worn spots. They can also rub against the foot, causing discomfort, even blisters. Think smooth when spinning the yarn for your sock feet.

It all boils down to this: Imagine the socks you want, then plan the fibres, colours, textures, fibre prep, and spinning method to best complement those socks. If you wish, break the sock into regions, and spin a different yarn for each! Extra durable yarn for heel and toe, for example, or smooth for lace patterning in the leg, fluffier for the foot. It's all possible for the handspinner.

Twist and Ply

I have found that spinners almost universally believe sock yarns need a lot of twist to be durable. That's not my experience. I spin to a twist angle of about 15 degrees routinely, project after project. It works as well in plied sock yarns as it does in weaving singles. The bonuses are that your yarn will feel softer, it won't take nearly as long to spin and ply a balanced yarn, and the socks won't take as much fibre. I've seen twist angles as high as 30 degrees used in sock yarns. I find such yarns to be very wiry and uncomfortable to knit and wear. Give a lower twist angle a chance and see what you think.

An area in which I spend more time than many spinners is in spinning a three-ply yarn rather than a two-ply. I have no direct comparison to offer, as I've never made two-ply yarn for socks. However, the more plies, the more durable the yarn will be. It will look less stringy at lower twist angles as well. If making yarns from layered batts, there will be fewer harsh contrasts (barberpoling or candystriping) between the colours since there are three (or more) colours interacting in any given area.

I've not yet spun a four-ply yarn for socks or anything other than small samples. It certainly makes a really nice, full, rounded yarn. I would say it's worth the effort for someone who really enjoys spinning, but it's not necessary for good sock yarn.

Some people believe the only yarn that will wear very well in socks is a cabled yarn. Certainly a cabled yarn, using as it does at least four well-twisted singles, and being plied twice over, is a very durable yarn. Maybe it would even stand the test of being worn inside rubber barn boots! (I'll have to check that out someday :) It's not necessary, though, for good sock yarn inc normal shoes or padded boots.

All this tends to debunk myths rather than give clear guidelines. Basically, to create durable, long lasting socks:

Choose your fibre wisely—no weak fibres, no fibres that are too fine to resist abrasion, and make sure they have good crimp for elasticity

Prepare them carefully so as not to weaken them, and to make sure they are equally well blended from beginning to end

Spin a smooth yarn with moderate twist, around 15 degrees Use three plies

When knitting, aim for a dense fabric, probably using much smaller needles than you normally would with that size yarn

Store the finished socks where bugs can't dine on them, and don't wear inside unpadded boots, especially if your feet are inclined to slide around inside

Darn your socks at the first sign of thinness, using yarn leftover from the socks and stored for the purpose—it's a lot easier to darn a thin spot than to darn holes

If you follow these guidelines, you'll be amazed at how much nicer your handspun socks are than socks made from commercial sock yarn. They'll be more beautiful and personal, of course. They will fit better and remain elastic. They'll be warmer because they're all natural fibres. And they will be very nearly as durable as socks of commercial sock yarn. I rarely wear any socks other than my handspun ones in the winter.

Are you a Weaver?

Do you have a loom at home and love what you do but feel a bit isolated?

Do you wish there was someone you could ask “should I take the blue stripe out or leave it in?....Why has my warp disappeared?....Why didn't my 'collapse weave' collapse?...What's the best way of finishing my rug?... Has anyone else ever woven this twill? I can't seem to get it to work! …. What on earth is diversified plain weave anyway?”

Are you thinking of changing your loom but unsure what you want?

Do you need to recharge your weaving mo-jo?

Would it help to have a some goals?

Would you just like a chance to chat with other weavers, share ideas and help one-another?

Well then, you need to join us at “Talk Weaving” at the Spinners and Weavers Workshop in Taunton.

Our next meeting is on Sunday 12 November from 11 to 3, the charge is £5 including coffee but please bring your own lunch. You would be very welcome to come along. Please call LesleyTook on 01823461640 or 07802 462875 or Sue Briggs on 07471 193945

Venture Forth!!!

Several members have taken their initiative to visit other guilds in the area. It is worth keeping an eye on the speakers and workshops available at other guilds in the area, our meetings usually span the other Saturdays in the month.

18th Century Dyeing in The South West

(Talk given in the July meeting. Apologies for late inclusion.)

Isabella Whitworth returned to the Guild to give another interesting and informative talk this time about the wool trade in the West Country specifically cloth dyeing in 18th Century Exeter.

As dyeing is a process requiring a large water supply dyers would have lived and worked down by the river amongst the other trades needing plenty of water such as the tanneries and shambles. It would be a dirty and smelly environment. This area in Exeter, known as Ex Island was originally outside the city walls and as well as being bounded by the river was supplied by leats. The area had been marsh land and the leats created when the marsh was drained in the Anglo-Saxon period. It is now an area in the centre of Exeter and has mostly been destroyed by modern development however traces of the old city's dye houses have been found on archaeological excavations and short areas of the leats are still to be seen above ground. There is also evidence of the past trade in the local names eg Lower Rackclose Lane. Rackclose being another name for the tentergrounds where the yards of newly fulled or dyed cloth were dried on large frames. Old paintings of Exeter show the long expanses of different coloured cloth stretched out to dry in the fields.

In the 1700s much of the wool industry was carried out at a domestic or cottage industry level and there were a number of centres were the cloth would be processed including dyeing eg Tiverton and Crediton for use and sale locally. However a lot of the commercial cloth for sale elsewhere especially abroad would be sent to Exeter for fulling and dyeing and then selling. Most of it would then be transported abroad or elsewhere in England from Topsham Wharf.

In Exeter there was a dyed cloth hall where the dyed cloth was collected and sold. Daniel Defoe wrote in his diary when visiting Exeter that the serge market was second in size only to Leeds. He estimated that the weekly value of the market was £60-100,000 [in today's money that would be £11-14 million]. Not only was it a big market but Exeter was reknown for the quality of its dyeing.

Despite the trade generating so much money the work of the dyer was hard, dangerous and probably for most poorly paid. The apprenticeship was 7yrs and it was a skilled profession. Good dyers were sought after. Though William Partridge in his 1823 'Practical Treatise on Dyeing' noted that a dyer needed to work in one place as the water quality was critical. His recipes for dyes might not work in another area where the water was different. So perhaps Exeter's reputation for high quality dyeing was as much due to the water characteristics as the dyers skills

The cloths were dyed in large tubs/vats. Celia Fiennes writing in the late 17th early 18th centuries records the long lengths of cloth on rollers being passed through the vats repeatedly until the desired colour was achieved. The process being repeated if over dyeing was required. The cloth was then rinsed in the leats, the dyers would pay to use bridges across the leats to stand on whilst doing this. It is not known how the leats were kept clean enough to be useful.

Various records give us an insight into the risks and dangers:-

1754 – A fire was recorded which required the leat normally closed at night to be left open in order to put it out. Fires must have been a significant risk with all the heating of the water required in the dyeing process.

1784 – Freezing winter conditions caused the leats to freeze and the fulling mills to be out of action for two weeks. This must have caused a lot of hardship through lost earnings.

1796 – A dyer fell into a furnace of boiling water and was scalded to death.

1803 – A drought caused a drying up of the water supply for eighteen weeks. Presumably during this time no dyeing would have been possible.

There are various records of dyes and mordants used. They used iron sulphate, copper, alum, wood ashes and nitric acid as mordants. Dyers were not allowed metal nails in their boots incase it affected the dyes.

We also know at least some of dyes used from various sources. In 1808 Mr Tucker recorded dyes he used in his stock book. They were mostly imported and included Madder, Logwood, Red Wood,

Cochineal, Bar Wood, Sumac. There are also records of ship carrying dyes eg Indigo, Sandalwood, Cochineal – Crutchley Archives.

The website Exeter's Memories has useful information for anyone who might like to visit Exeter to search for remnants of the leats.

Items for Sale

If your item is listed below and has now sold, please contact Sue Latimer - suelatim@gmail.com - to have it removed.

If you would like to list an item for sale, please contact Laura Tyley - lauratyley1@gmail.com